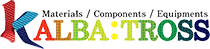

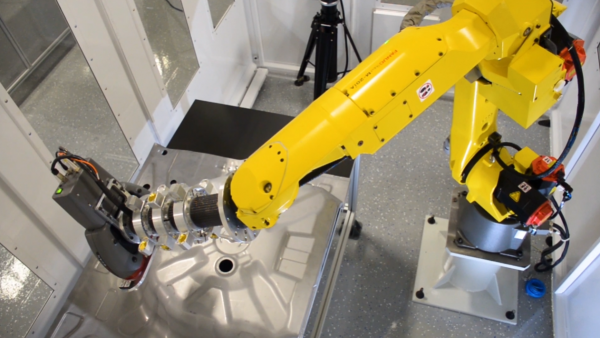

- SFIS stands for Smart Factory Inspection System, an integrated robotic system inspection automation solution.

- System designed for high accuracy and growing demand from the industry for automation

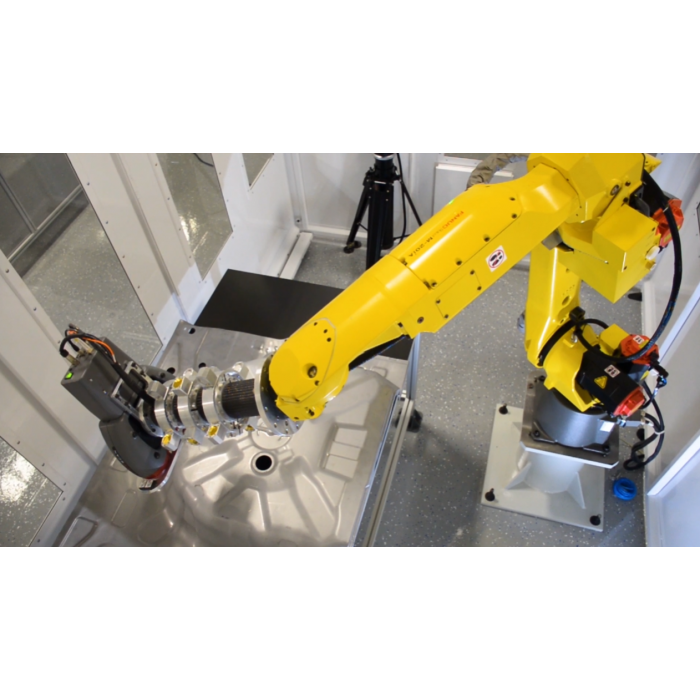

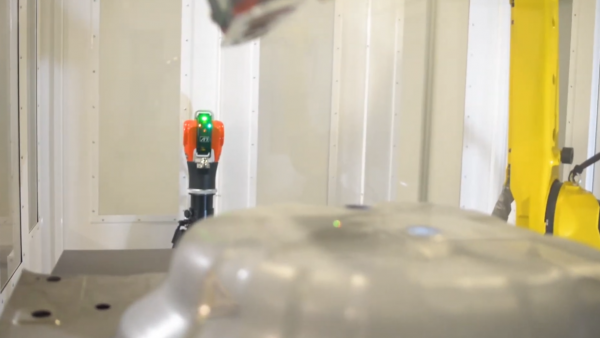

- This is a real-time 3D robot measuring smart inspection system with 6DoF (6 degrees of freedom).

- Quick contactless inspection and precise inspection are possible.

- Software enables statistical process management and system construction.

SFIS(Smart Factory Inspeciton System)

Feature

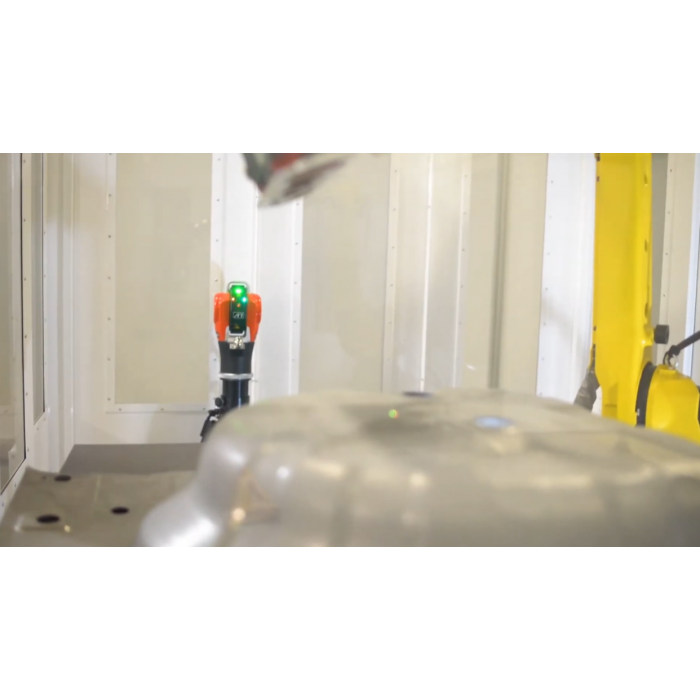

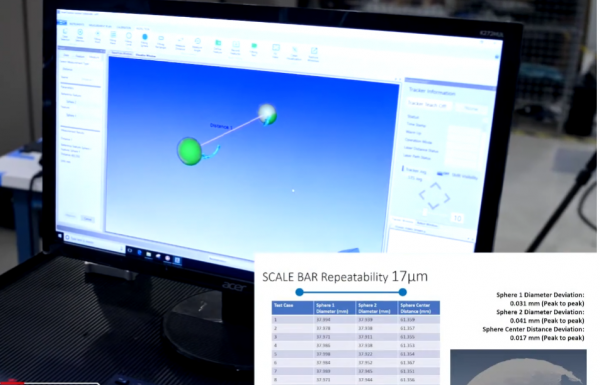

- Accuracy

- Provides full 3D matching accuracy ±120 μm (2σ), surface single scanning accuracy ±50 μm (2σ), and hall center measurement accuracy ±25 μm (2σ).

- Speediness

- Part Transfer -> Measurement Alignment -> Scanning -> Data Processing -> Semi-Automation Process of Inspection Results Output

- Single scanning measurement completed within seconds, Full 3D scanning measurement completed within minutes.

- Convenience

- System operation of non-professional quality inspection personnel

- Customer Process Response

- Development of system integration software to provide solutions tailored to customer processes

- Widespread Utilization

- Various scanning performance without restriction of physical properties (color, reflectance, material, etc.) of the measurement object

- Build semi-automatic, fully automatic, in-line, and off-line inspection systems

- Establishment of a detailed inspection system for finished products and parts in the automobile, aviation, machinery, and electronics industries