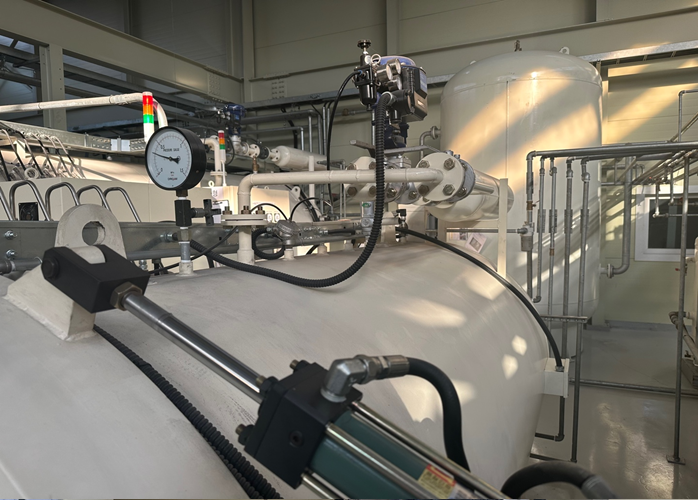

- Pressure-resistant equipment to harden to maintain shape when manufacturing carbon fiber parts in the automotive and aviation sectors

Autoclave

A small 50 tons

Feature

- Molding Equipment Specialized in Small Volume Production of Complex-Shaped Multi-Various Types for Aerospace Radiated Carbon Composites.

- It is difficult to implement with a press, but it is possible to mold the shape of a difficult aerospace part.(undercut shape, etc.)

- Molding equipment specialized in mass production using multiple molds of the same shape.

- Equipment that can secure excellent productivity when using CFRP molds.

SPECIFICATION

| Classification | Major Specifications |

|---|---|

| Autoclave Body - ∅1500×2500L | 9.9kg/㎠×200℃(max.250℃) |

| Clamp ring & hinge | Forging & Housing |

| Circulation Fan | 7.5kw×4P Motor & Housing |

| Vent Silencer & Control Valve | 80dB or less |

| Insulation 50T, Rock Wool | SUS #304 0.6t Sheet Cover |

| Safety Valve | CEAD KOSHA(certified article) |

| Cooling Coil | SUS #304 Fin Tube Type |

| Internal Rail & Support | - |

| Gage, Sensor, Switch | 15A, Temp, Press |

| Electric Heater 27kw×2=54㎾ | TPR 2Group |

| Door Packing | Silicon |

| Duct, Wiring | 380V AC 3∅ 60Hz |

| Inspection (KOSHA Cert.) | Material, X-Ray, Hydro Test |

| Sanding &. Painting | Epoxy(designated color) |