- For faster large and or more accurate large scale 3D printing solutions

- The BEAD is a hybrid solution, combining the finish and tolerances subtractive manufacturing offers with the sustainability of additive manufacturing into one system.

- Enables 3D printing close to the net shape of the part and is later milled to the required tolerances using a CNC milling machine.

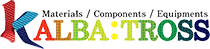

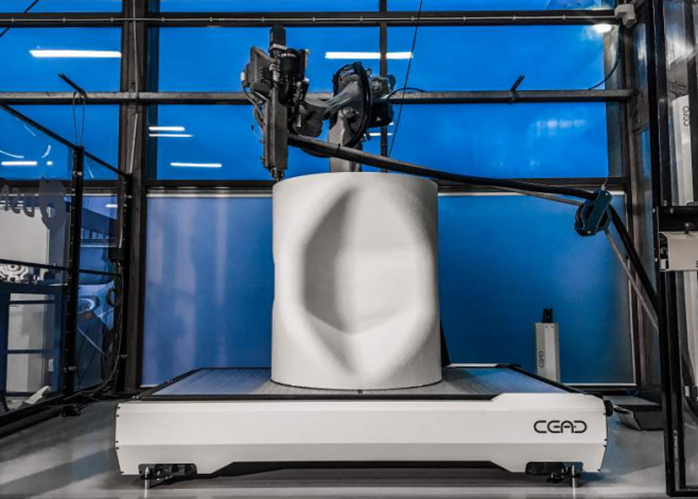

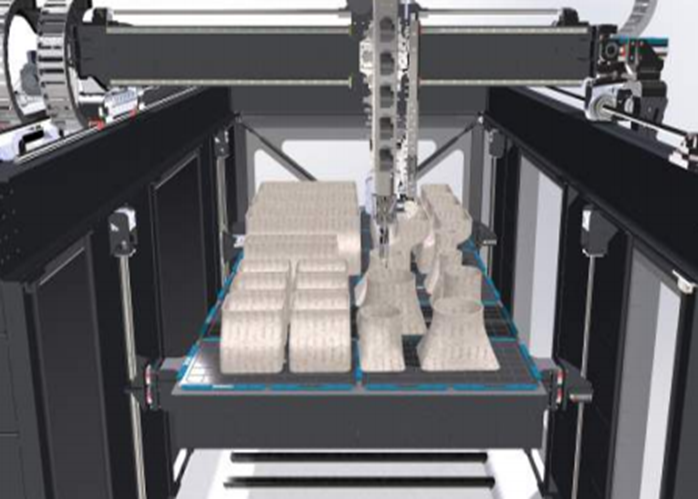

- The CFAM Prime is engineered to run production and therefore focusus on printing speed and reliability.

- It’s ideal for the efficient production of multiple.

- It’s a large parts in one production run and a complete turn key machine.

BED/CFAM PRIME

Gantry Based Solutions

Feature

- BED

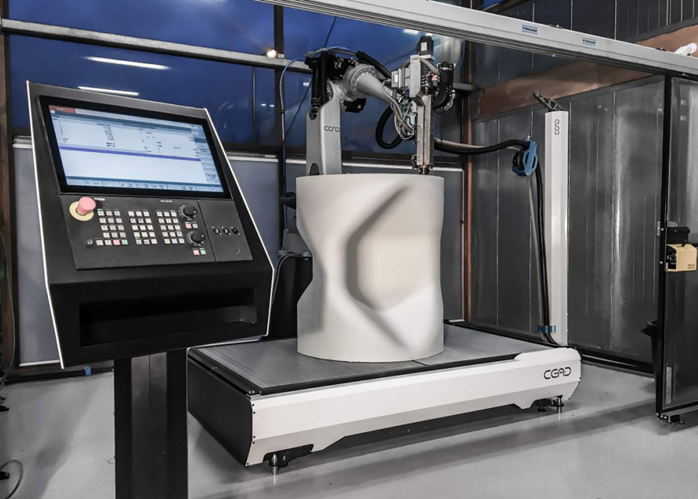

- Dimensions: X : 6000 to 50000 mm | Y : 2600 to 11000 mm | Z : 1500 to 5000 mm

- Milling tool change position: 8 to 60 positions

- Milling spindle: 15 to 30 kW

- Milling Accuracy: 0.02 mm/m

- Printing Extruder temperature: 400 °C

- Printing Extruder output: 12 – 80 kg /hr

- Integrated interface with Siemens Sinumerik

- Suited for virtually all the different thermoplastics.

- CFAM PRIME

- Build volume of 4m x 2m x 1.5m

- Multi part production

- Fully enclosed environment

- Continuous fibres

- Average output of 15 kg/hr

- Siemens Sinumerik

- Virtually all thermoplastics

SPECIFICATION

| Classification | Major Specifications |

|---|---|

| Print bed area(optional:heated print bed) | starting from 2000x1200mm |

| Printing speed | max. 15m/min |

| Extruder output | up to 12kg/hour |

| Extruder temperature | up to 400°C / 752°F |

| Nozzle size | 2 - 12mm |

| Software | CEAD custom software |