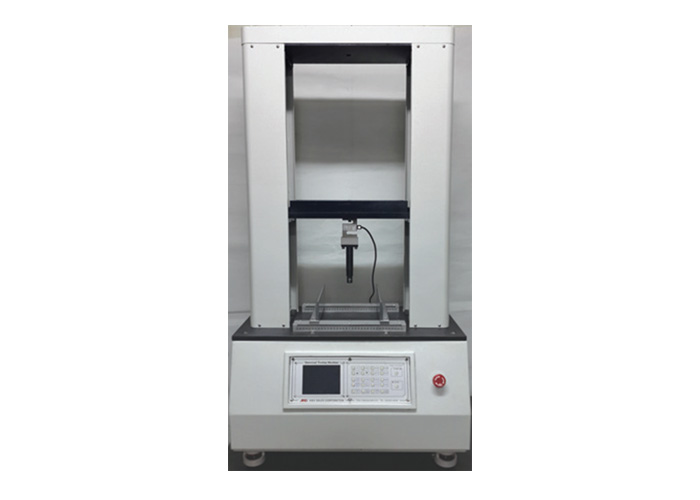

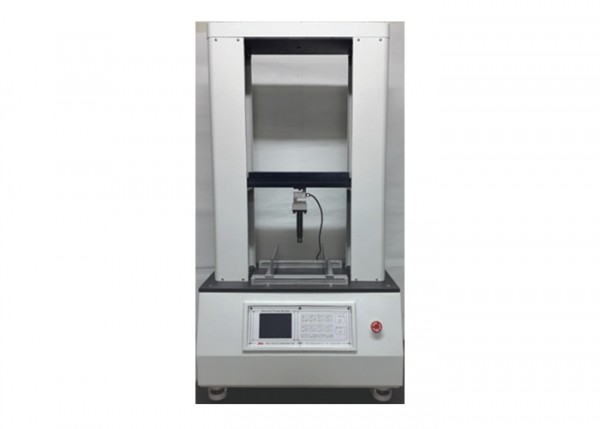

- This device is capable of testing tensile/compressive strength and bending of various materials and products such as plastic, metal, and rubber.

- Reliability / Durability / Education & Scientific Equipment

Universal Testing Machine

Feature

- It is highly stable owing to the solid structure.

- Tensile/compressive rates adjustable

- Possible to control the speed precisely by using the AC servomotor.

- Possible to control testing devices and monitor the data by using a PC.

- The Load Cell, a heavy load detector, is applied.

- Multi-level test speed controlling: The user may select one of the 3 speed levels or use the automatic speed change function before/after each yield section.

- Removal of mesh load: Automatic removal of tensile and compressive loads upon material overlapping.

- Test speed: Basic setting: 0.01–500 mm/min

- It is possible to complete the test by maintaining or removing the load with no material fracture involved during the tensile test.

- Steady movement test

SPECIFICATION

Scroll left/right.

| Model | AD-500K | AD-1T | AD-2T | AD-5T | AD-10T | AD-20T | AD-30T | AD-5T |

|---|---|---|---|---|---|---|---|---|

| Max, Capacity | 500kg | 1ton | 2ton | 5ton | 10ton | 20ton | 30ton | 5ton |

| Loading System | Computerized Numberical Control System Operated | |||||||

| Power Source | AC 220V, 3Phase, 50/60㎐ | |||||||

| Resolution - 16Bits | 0.017kgf | 0.03kgf | 0.07kgf | 0.17kgf | 0.3kgf | 0.7kgf | 1kgf | 1.7kgf |

| Monitor capacity | 0.4㎾ | 0.75㎾ | 1㎾ | 2㎾ | 3.5㎾ | 5㎾ | 7.5㎾ | 15㎾ |

| Cross-Head | 1~500㎜/min | |||||||

| Accuracy |

Testing Load Accuracy - Within ± 0.4% Testing Speed Accuracy - Within ± 0.5% |

|||||||

Cross-Head |

Fast ▲ ▼, Slow ▲ ▼(use Calbration Mode) - Any time after P.C on (Test, Stop, Original) Key - After U.T.M Program |

|||||||

| Safety device | Emergency S/W, N, F, B, Software Protect of 95% F.S (Full Scale) | |||||||

| Stroke Limiter | 4 Point Limiter | |||||||

| Fracture detection | 1. Auto 2. User Defined | |||||||

| Sensor | Load Detector - Load cell, Stroke Detector - Encorder (1000 pulse) | |||||||

| Reducer | Motorvario (40:1, 80:1) | |||||||

| Screw | Ball Screw | |||||||

| Column | 2 | 2 | 2 | 4 | 4 | 4 | 4 | 4 |

| Test Mode | Tensile, Compress, Tear, Cycle, Bending 90" Peel, Relaxation Test | |||||||

| Jaws | Flat Jaws 1 set | |||||||

| Load cell accuracy | Within ±0.03% (F.S), Maker - A & D, Korea | |||||||

| Control Board | A/D Board - 16 Bits, D I/O-8ch, 16 Bits Micon Board | |||||||

| Option | Jig, Program, Computer, Extenso-Meter | |||||||

- * Basic specifications customizable with different conditions of distance, weight, etc.

- * The external appearance and specifications may be changed for improvements in product performance and as ordered without prior notification.

- * For special specifications other than those stated above, customized production is possible based on advance consultation.