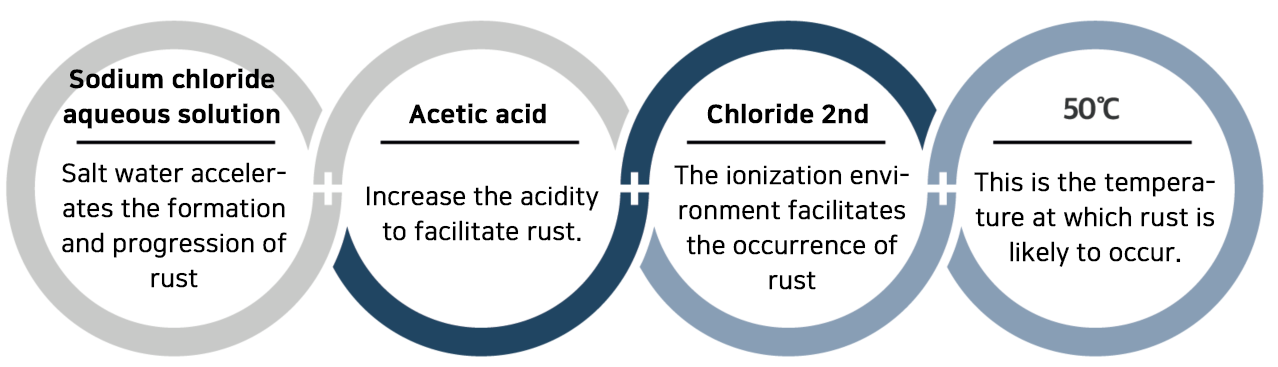

- The Cass testing method uses a spray tester to examine the corrosion resistance performance of plating. It was developed to conduct testing in an adverse corrosion environment and is used for accelerated corrosion tests of automotive components and accessories such as chrome and nickel.

Reliability / Durability / Training & Scientific Equipment

Automatic Cass Spray Tester

Feature

- This is useful in testing a decorative plating made of copper, nickel, and chrome, or nickel, and chrome. It is also appropriate in testing aluminum anodic oxidation platings.

- The automatic Cass Spray Tester is produced in compliance with the KS D 9502.

SPECIFICATION

Scroll left/right.

| Model | AD-6200N | AD-6300N | |

|---|---|---|---|

| Dimension | In | 900 x 600 x 600㎜ (W x D x H) | 1,200 x 800 x 600㎜ (W x D x H) |

| Out | 1,500 x 1,100 x 1,700㎜ (W x D x H) | 1,900 x 1,100 x 1,800㎜ (W x D x H) | |

| Material | In | PVC 10T | |

| Out | Profile 40 x 40 Support with Cover | ||

| Door | PVC Molding Door | ||

| Controller | Digital Touch Screen Temperature | ||

| Chamber Temperature | 50℃±1℃ | ||

| Saturation bottle temperature | 60℃±1℃ | ||

| Injection quantity | 1.5㏄/hr | ||

| Power | 220 V, single-phase, 50/60 ㎐ | ||

| Standard accessories | Basic 3-colored light bar to indicate operation, pause, and error | ||

- * The external appearance and specifications may be changed for improvements in product performance and as ordered without a prior notification.

- * For special specifications other than those stated above, customized production is possible based on advance consultation.