- CF RobⓇ checks the quality of Carbon Fiber Filament in real time to ensure material safety and effectively detect Fiber Errors in advance.

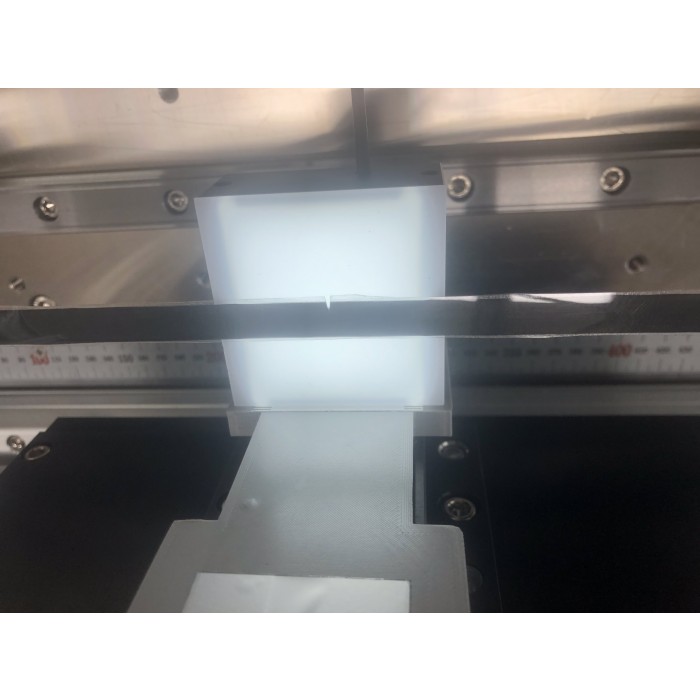

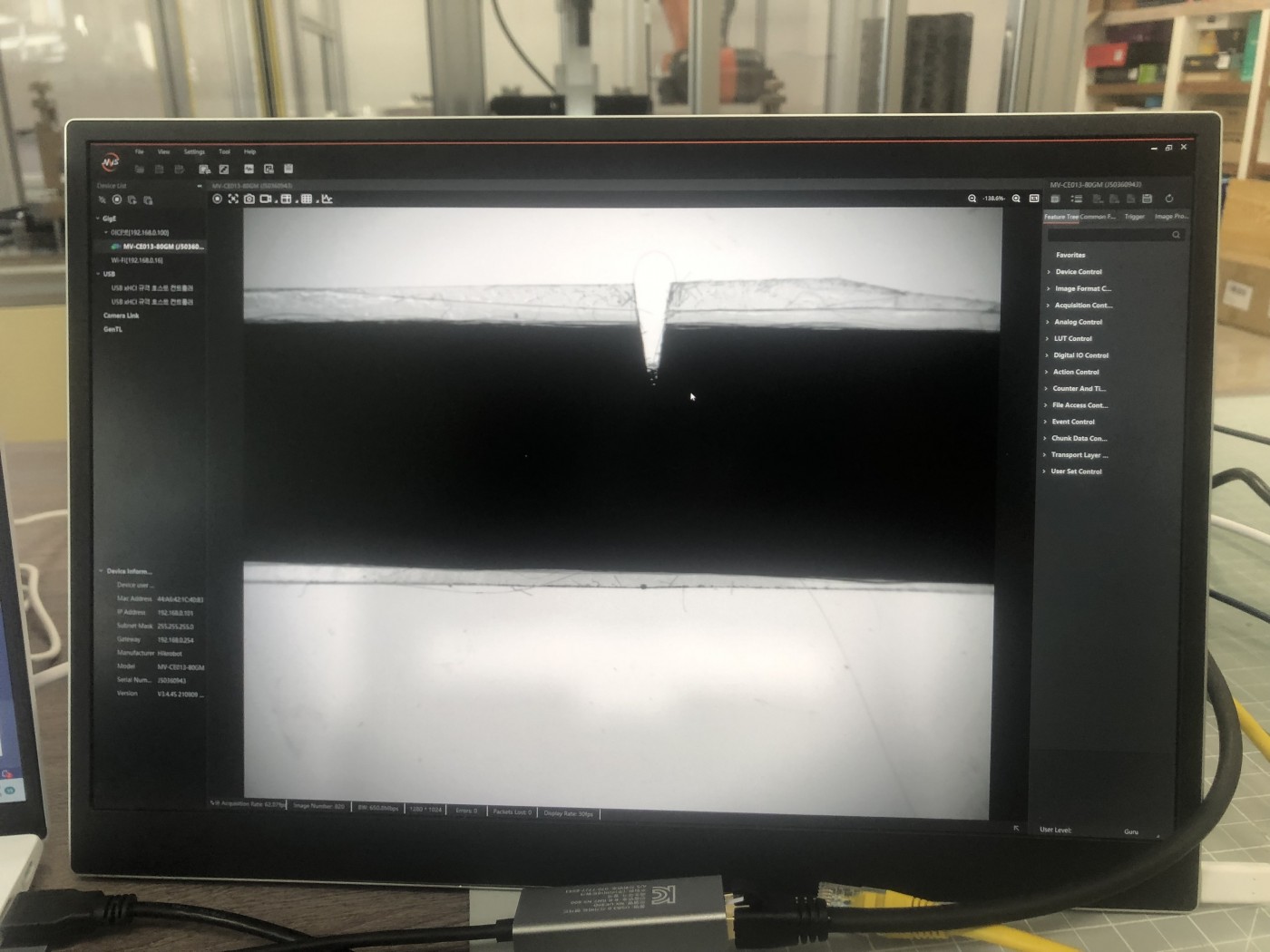

- The Sensor's defect data and the shape of the actual defect can be identified and analyzed from a quantitative perspective.

- Scanned data and images can be viewed in dedicated software and can be automatically classified by fiber defects to effectively manage quality.

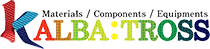

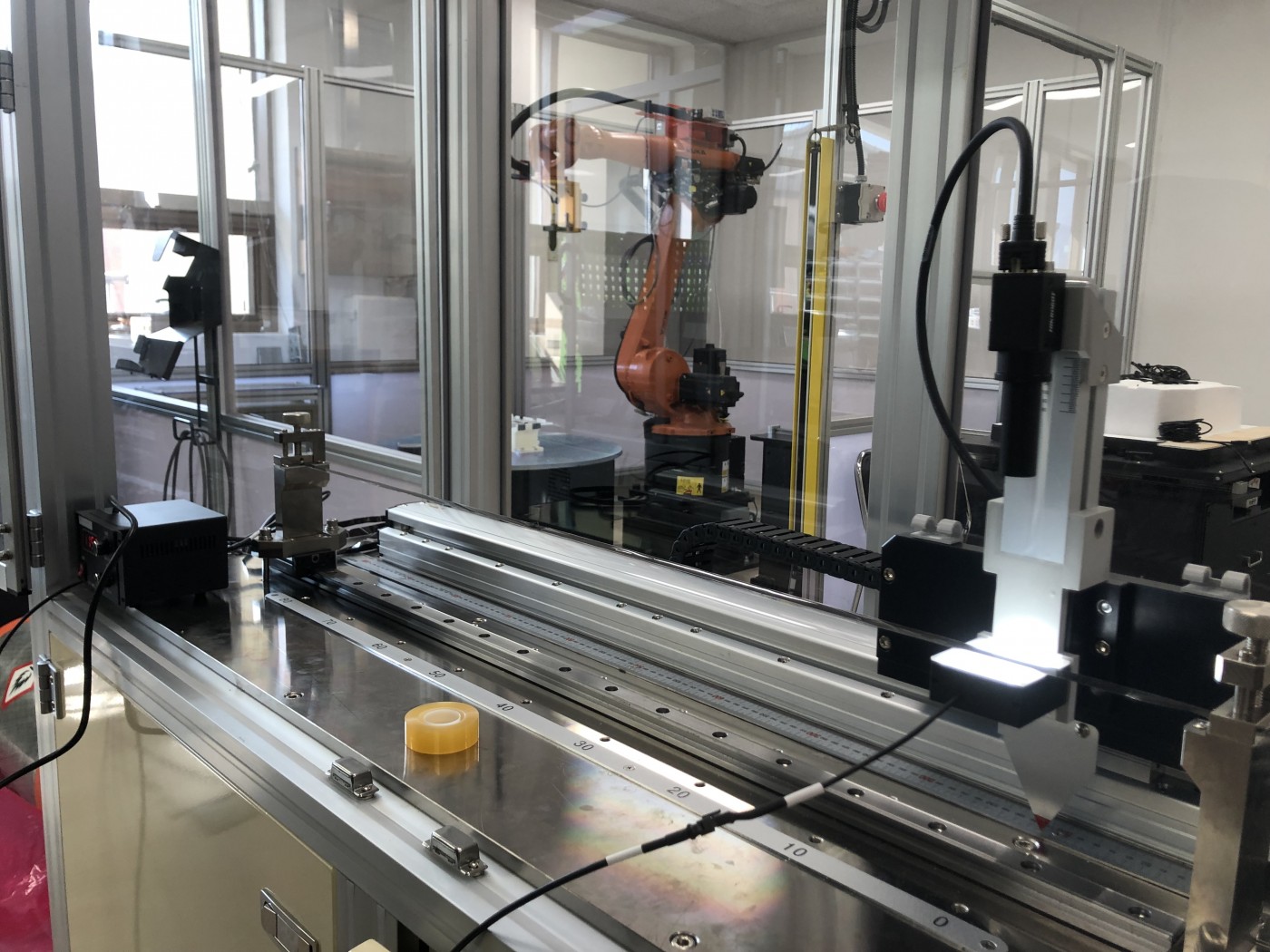

CF RobⓇ Vision System

Carbon Fiber Filament Winding Vision Inspection System

Feature

- Effectively inspect carbon fiber defects during production of carbon fiber toe.

- Physical property data and images of carbon fiber filaments can be secured.

- Effectively detect and classify defects using dedicated software.

- Speed, accuracy, repeatability.

- Quantitative measurement of structured features.

- Quality management data can be used in the future by utilizing the detected image.

- Users can judge the actual shape and image of the defective data.

SPECIFICATION

좌/우로 스크롤하세요.

| Classification | Major Specifications | |

|---|---|---|

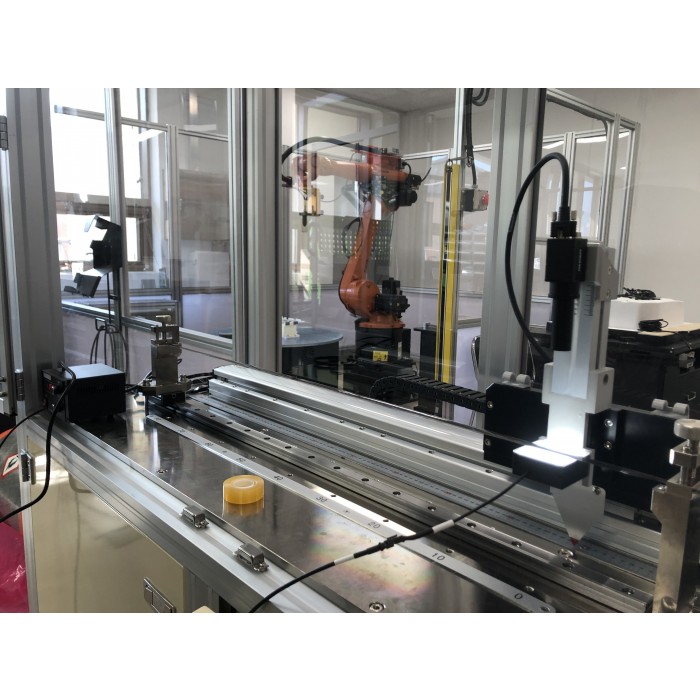

| Equipment Configuration | 1 x Area Scan Camera, Lens | |

| 1 x Control Unit | ||

| 1 x Backlight | ||

| 1 x Power Supply | ||

| Pixel size | 4.0 µm x 4.0 µm | |

| Sensor size | 1/2.7'' | |

| Resolution | 1280 x 1024 | |

| Dimension | 29mm x 29mm x 42mm(1.1'' x 1.1 '' x 1.7'') | |

| Power consumption | 2.4W@12VDC | |

| Color Temperature | 5,200K | |

| Illuminance | 4,000Lux | |

| Intergration | Library DLL for C# | |

| Interface | UDTp, TCP-up, Modbus via Ethernet | |

| Ingress protection | IP30 | |

| Required conditions | Working temperature : 0 °C ~ 50 °C | |

| Storage temperature : -30 °C ~ 50 °C | ||

| Certification | CE, FCC, RoHS, KC | |